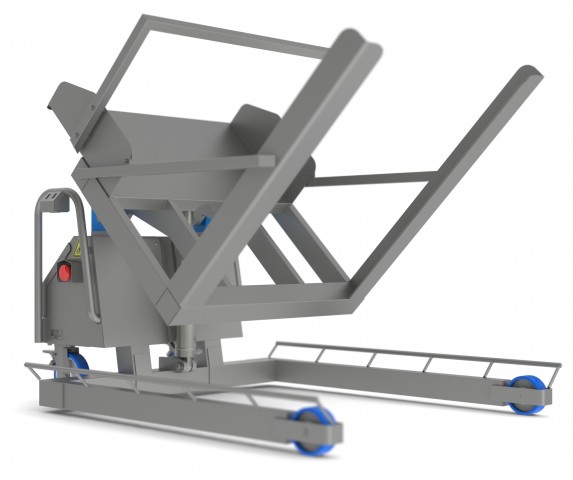

Tipping machine designed to unload large plastic containers, pallet boxes and other large vessels.

A larger unit than the standard tipping machine, which could be displaced occasionally. The machine can easily recieve loads from manual and electric transpallets trucks.

IMPROVEMENT OF PROCESS: TIPPING MACHINE FOR BONING PERSONNEL

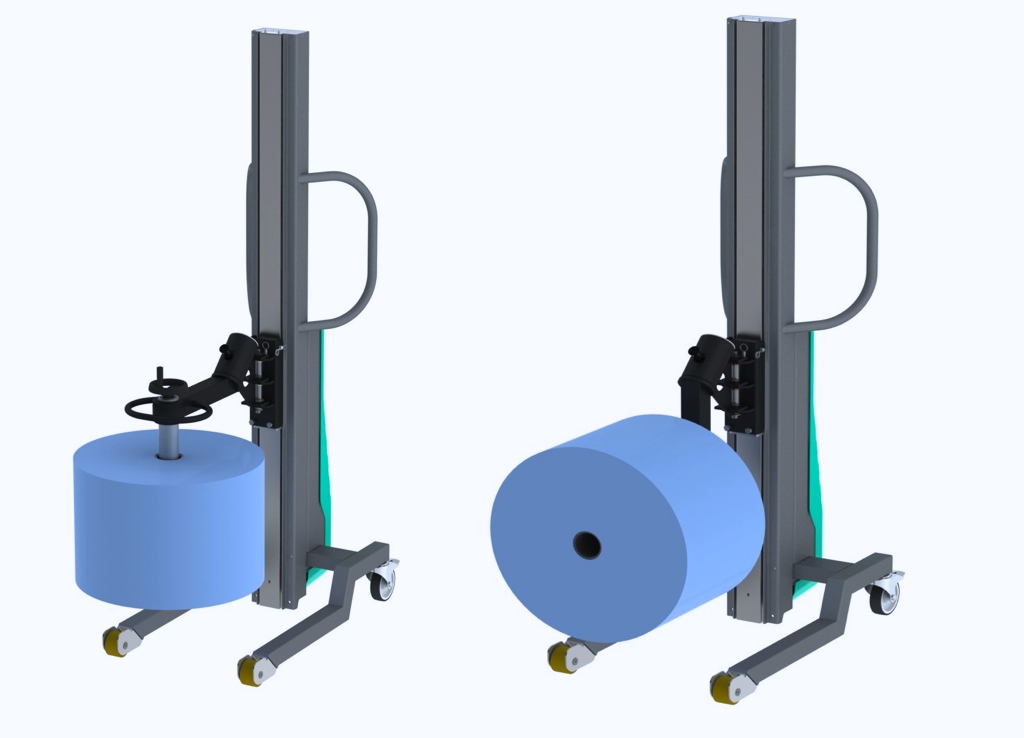

Simple and easy to use machines that enable to improve production perfomance and decrease risk of accident at work.

HEALTH AND INCREASED PRODUCTIVITY: LESSER RISK OF BACK INJURIES, HIGER PRODUCTION RATE

This model is to be operated as a transpallet to collect a container. Eliminating manual lifting operations allows to never bend or lean, thus reducing the risk of injuries.

This model is designed to be installed in specific unloading spot. Tanks with food products are conveyed to such spot and inserted into the turning machine using a transpallet or a forklift truck.

The load is then inclined with a gradual motion, as the contained product starts to flow down until the maximum inclination angle is met. Eliminating manual lifting operations allows to never bend or lean, thus reducing the risk of injuries.

POWERFUL RECHARGABLE BATTERY

SAFE OPERATION: non-motorized drop down, acoustic warning.

HYGIENE AND FOOD SAFETY: stainless steel for better sanitary conditions.

FEATURES:

– single hydraulic cylinder

– acoustic warning signal

– strong turning wheels with brakes

– powerful rechargeble battery

– double indipendent controls on each side

Italiano

Italiano English

English